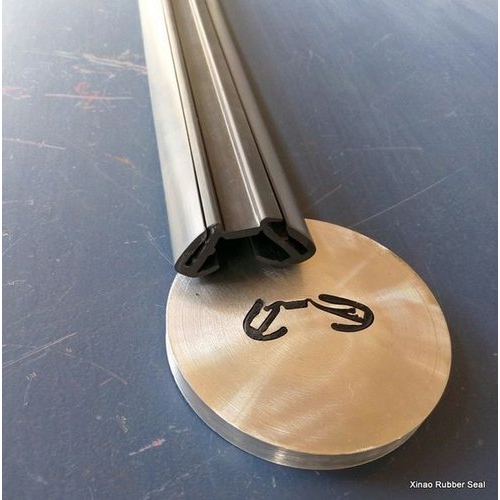

Copper Extrusion Die

Product Details:

X

Product Description

Copper extrusion dies are precision-engineered tools used to shape copper into various profiles by forcing it through a die under high pressure. These dies feature essential components like the die body, die insert, and die cavity, which define the shape and dimensions of the extruded copper product. Crafted from high-strength materials such as tungsten carbide or hardened steel, they ensure durability and consistent performance. Designed using advanced CAD technologies, they are applied in industries like electrical, automotive, aerospace, and construction for making wiring, tubing, and connectors. Advanced manufacturing techniques ensure precision, longevity, and adaptability to meet diverse application requirements.

Enter Buying Requirement Details

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free