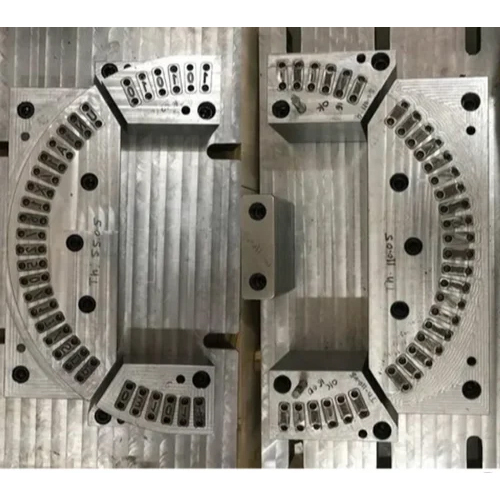

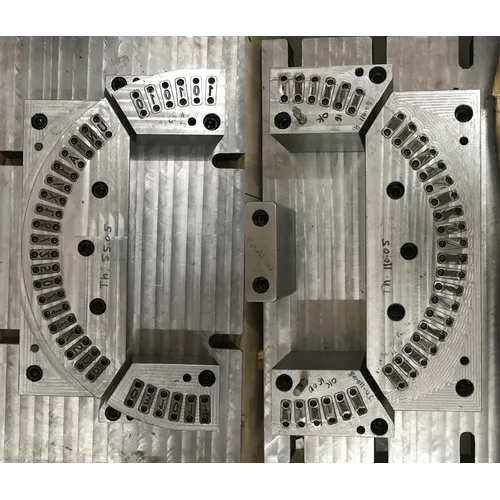

Plastic Injection Mold

Product Details:

- Usage Industrial

- Color Silver

- Size Standard

- Product Type Plastic Injection Mold

- Material Steel

- Warranty yes

- Click to View more

Plastic Injection Mold Price And Quantity

- 28000 INR/Piece

- 1 Piece

Plastic Injection Mold Product Specifications

- Industrial

- Steel

- Standard

- Plastic Injection Mold

- yes

- Silver

Plastic Injection Mold Trade Information

- 1000 Piece Per Month

- 7 Days

Product Description

An Injection of Plastic A precisely designed tool called a mould is used in the injection moulding process to make intricate plastic pieces. Its major parts for shaping, forming, and ejecting plastic components include the mould cavity, core, runner system, sprue, and ejector system. High-strength materials like steel or aluminium, which are selected for their durability and heat resistance, are commonly used to make these moulds. They manufacture parts in a variety of sizes and dimensions and are versatile across industries such as consumer goods, electronics, automotive, medical, and aerospace. High efficiency, accuracy, and scalability are made possible by the injection technique, which guarantees reproducible, reasonably priced production of complex designs.

| Usage/Application | Industrial |

| Technique | Injection Molding |

| Material | Plastic |

| Automation Grade | Semi-Automatic |

| Color | Silver |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS