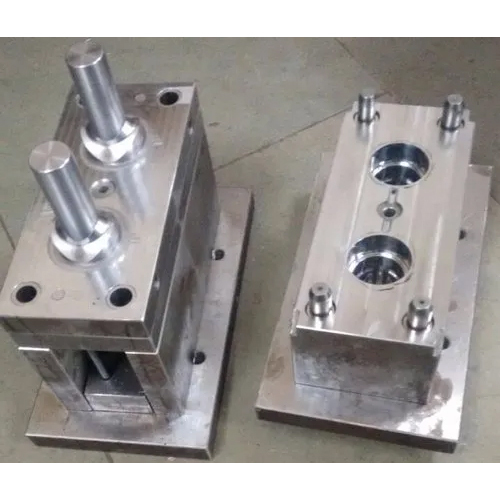

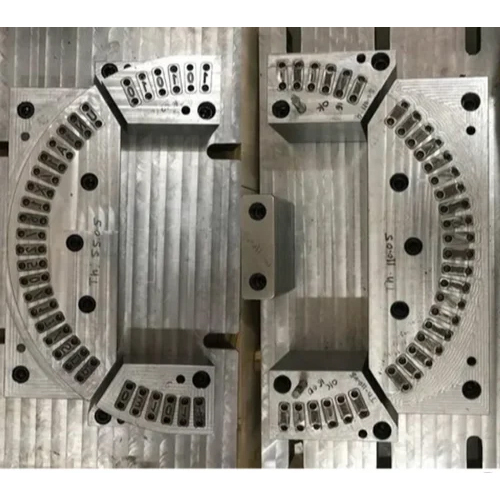

Plastic moulds

Product Details:

- Product Type Plastic Injection Mould

- Color Silver

- Usage Industrial

- Material Metal

- Shaping Mode Other

- Warranty yes

- Click to View more

Plastic moulds Price And Quantity

- 1 Set

- 50000 INR/Set

Plastic moulds Product Specifications

- Silver

- yes

- Plastic Injection Mould

- Industrial

- Metal

- Other

Plastic moulds Trade Information

- 1000 Set Per Month

- 7 Days

Product Description

An Injection of Plastic In order to create plastic parts, molten plastic is injected into a defined cavity using a mould, a precise instrument. The plastic then cools and hardens to take on the required shape. The mould cavity, core, sprue, runner system, and ejector system are all crucial parts that play a part in forming, guiding, and releasing the finished product. Steel and aluminium, which are renowned for their strength and resilience to heat, are the main materials used to make these moulds. They facilitate the effective manufacture of parts in a range of sizes and dimensions using injection moulding techniques, guaranteeing accuracy and repeatability, and are utilised in a variety of industries, including consumer products, automotive, electronics, medical, and aerospace.

| Technique | Injection Molding |

| Runner Type | Cold Runner |

| Automation Grade | Automatic |

ï

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free