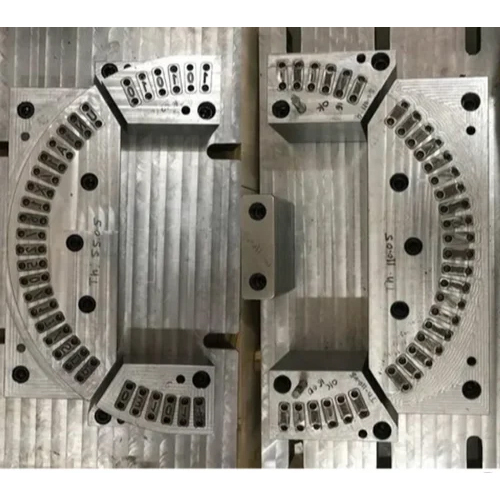

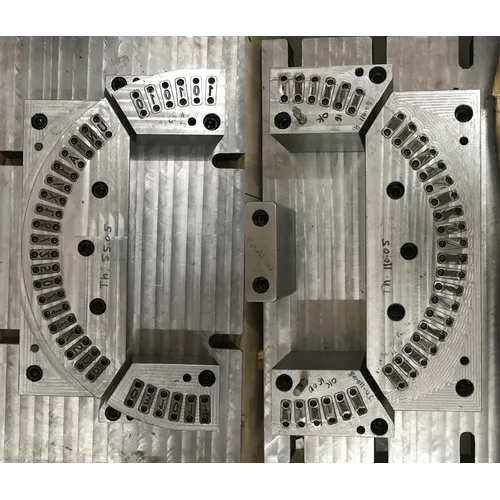

Plastic Molds

Product Details:

- Color Silver

- Usage Industrial

- Size Standard

- Product Type Plastic Molds

- Material Steel

- Warranty yes

- Click to View more

Plastic Molds Price And Quantity

- 50000 INR/Set

- 5 Set

Plastic Molds Product Specifications

- Standard

- Industrial

- Silver

- yes

- Steel

- Plastic Molds

Plastic Molds Trade Information

- 1000 Set Per Month

- 7 Days

Product Description

Plastic molds are precision-engineered tools used to shape molten plastic into specific forms, creating parts for various industries. Made primarily from materials like steel, aluminum, or hardened alloys, these molds consist of key components such as cavities, cores, and ejector systems, which shape, cool, and release the finished plastic part. Known for their durability, cost-efficiency, and versatility, plastic molds are widely used across industries like automotive, electronics, medical, and consumer goods. Techniques like injection molding, blow molding, and rotational molding ensure precise shaping. They come in diverse dimensions, tailored to fit complex designs and mass production needs.

| Usage/Application | Injection Moulding |

| Automation Grade | Automatic |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS