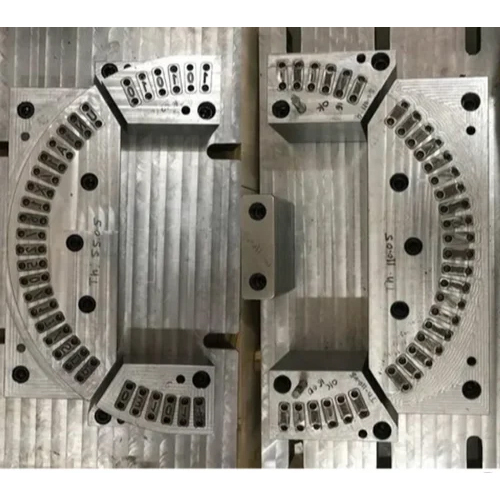

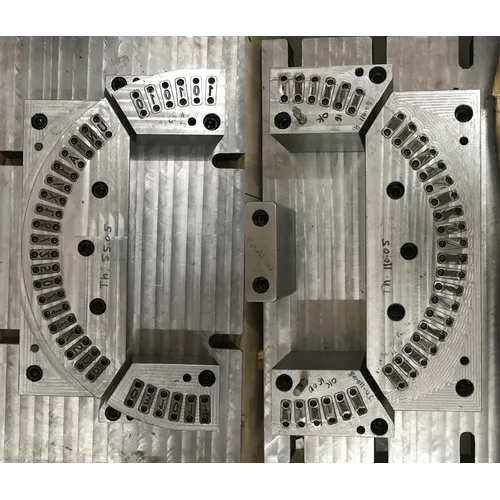

Precision Moulds

Product Details:

- Size Standard

- Product Type Precision Moulds

- Usage Industrial

- Color Silver

- Material Steel

- Warranty 1 Year

- Click to View more

Precision Moulds Price And Quantity

- 25000 INR/Set

- 1 Set

Precision Moulds Product Specifications

- Silver

- Precision Moulds

- Steel

- Industrial

- 1 Year

- Standard

Precision Moulds Trade Information

- 1000 Set Per Month

- 7 Days

Product Description

High-accuracy instruments called Precision Moulds are used to sculpt molten materials into precise, complex shapes for production. These moulds are made of sturdy materials like carbide, aluminium, or hardened steel and include necessary parts like cooling channels, cores, ejector systems, and cavities. They provide consistent part output, accurate shaping, and effective cooling. Precision moulds are frequently utilised in industries such as consumer products, electronics, medical devices, and automobiles because of their strength, accuracy, and longevity. These instruments are used in processes like compression moulding, blow moulding, and injection moulding. The complexity of the design and the demands of production determine their dimensions.

| Part Material | Zinc Alloy |

| Surface | Finishing |

| Application | Home Use, Household Appliances, Car, Commodity |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS