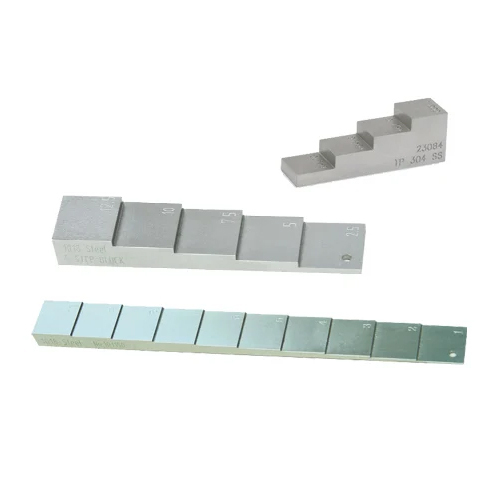

Notches For UT Calibration

Notches For UT Calibration Specification

- Color

- Silver

- Power Supply

- Electric

- Usage

- Industrial

- Product Type

- Notches For UT Calibration

- Operate Method

- Manual

- Material

- SS

- Application

- Industrial

Notches For UT Calibration Trade Information

- Minimum Order Quantity

- 10 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Notches For UT Calibration

Notches for UT (Ultrasonic Testing) calibration are precisely machined reference features used to ensure the accuracy and reliability of ultrasonic testing equipment. Made from high-strength materials like steel, aluminum, or specialized alloys, these notches act as calibration standards for measuring sound wave propagation. They are critical in industries such as aerospace, automotive, construction, and oil and gas. Various types include side-drilled holes, grooves, or flat-bottom holes, tailored to specific testing requirements. These notches come in defined dimensions to support effective, accurate ultrasonic inspections across materials and applications.

| Block Size | 2.5" x 6.0" |

| Thicknesses | 0.25 mm |

| Applications | Ultrasonic Testing |

| Material | Stainless Steel |

Price 2000.00 INR/ Piece

- Minimum Order Quantity

- 10 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Calibration Block Category

Step Wedge Calibration Block

Price 25000 INR / Set

Minimum Order Quantity : 1 Set

Material : SS

Color : Silver

Operate Method : Manual

Product Type : Step Wedge Calibration Block

Send Inquiry

Send Inquiry Send SMS

Send SMS