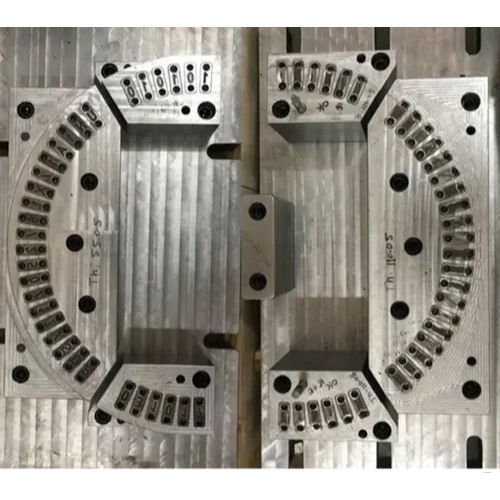

Injection Molding Dies

Injection Molding Dies Specification

- Usage

- Industrial

- Material

- Metal

- Shaping Mode

- Instrusion Mould

- Size

- Standard

- Product Type

- Injection Molding Dies

- Color

- Silver

- Warranty

- yes

Injection Molding Dies Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Injection Molding Dies

Moulding via Injection In the injection moulding process, dies are precisely designed instruments that mould molten plastic into the required shapes. These dies provide longevity, accuracy, and resistance to wear since they are made of high-strength materials like tungsten carbide, aluminium, or hardened steel. Cavities, core pins, ejector systems, and cooling channels are essential parts that cooperate to effectively shape, cool, and release moulded objects. By producing intricate, consistent parts, they enable high-volume production in sectors including consumer goods, electronics, automotive, and healthcare. These dies, which are made to precise measurements, maximise production using methods like rapid prototyping and injection moulding.

| Material | Metal |

| Automation Grade | Semi-Automatic |

| Packaging Type | Standard |

| Color | Grey |

| Weight | 30 kg |

Price 20000.00 INR/ Set

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dies & Mould Category

Metal Stamping Die

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Iron

Usage : Industrial

Warranty : 1 Year

Product Type : Metal Stamping Die

Precision Dies

Price 5000 INR / Set

Minimum Order Quantity : 1 Set

Material : Steel

Usage : Industrial

Warranty : 1 Year

Product Type : Precision Dies

Plastic Injection Mold

Price 28000 INR / Piece

Minimum Order Quantity : 1 Number

Material : Steel

Usage : Industrial

Warranty : yes

Product Type : Plastic Injection Mold

Embossing Die

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Usage : Industrial

Warranty : yes

Product Type : Embossing Die

Send Inquiry

Send Inquiry Send SMS

Send SMS